Crafting Durability: CSA Cement and Expansive Solutions for Diverse Applications

Crafting Durability: CSA Cement and Expansive Solutions for Diverse Applications

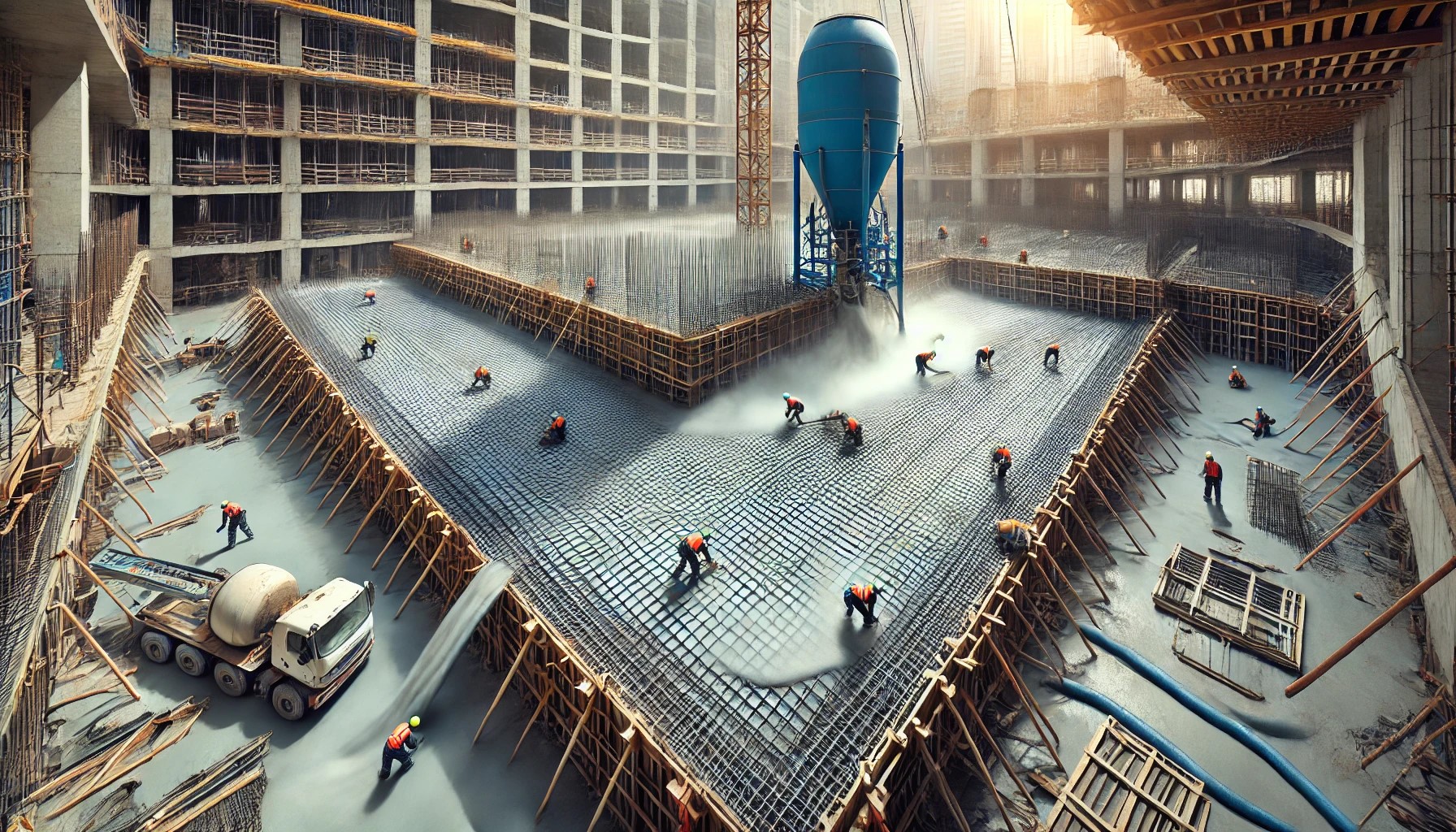

Calcium Sulfoaluminate (CSA) Cement and CSA Expansive materials are revolutionizing the construction and oil & gas industries with their unique properties and diverse applications. These advanced materials offer significant advantages over traditional cement, making them highly sought after for various specialized applications.

CSA Cement: High Performance and Versatility

CSA Cement stands out for its exceptional early strength development, durability, and reduced shrinkage characteristics. CSA Cement achieves high early strength within a few hours, unlike traditional Portland cement, making it ideal for rapid construction projects and emergency repairs. This rapid strength development allows structures to be used or loaded much sooner than those built with conventional cement.

CSA Cement is particularly valued for Dry-mix and Glass Fiber Reinforced Concrete (GFRC) applications in construction. Its high-performance characteristics make it an excellent choice for specialty cements in demanding environments. For instance, CSA Cement is used to construct bridges, airport runways, and high-traffic roadways where early strength and durability are crucial.

Beyond construction, CSA Cement is also utilized in the oil & gas industry as an additive for cementing. Its ability to develop strength quickly and maintain stability under high temperatures and pressures makes it suitable for well-cementing operations. Additionally, CSA Cement’s resistance to sulfate attack and chemical corrosion enhances the longevity and reliability of oil wells.

CSA Expansive: Enhancing Structural Integrity

CSA Expansive materials are designed to combat shrinkage and cracking in concrete structures. By producing controlled expansion, these materials counteract the natural shrinkage that occurs as concrete cures, thus enhancing the structure’s overall durability and integrity.

In construction, CSA Expansive materials are used in Dry-mix and GFRC applications to create specialty cements less prone to cracking and shrinkage. Using CSA Expansive materials ensures that structures remain stable and durable over time, reducing maintenance costs and extending their service life.

The oil & gas industry also benefits from the unique properties of CSA Expansive materials. When used as additives for cementing, these materials help maintain wellbore integrity and prevent casing failures. The controlled expansion provided by CSA Expansive materials ensures a tight seal in the wellbore, preventing unwanted fluids’ ingress and enhancing the well’s overall stability.

Conclusion

By leveraging the unique properties of CSA Cement and CSA Expansive materials, industries can achieve greater efficiency, cost savings, and structural integrity in their projects. Whether for rapid construction, specialized cementing operations, or enhancing water treatment facilities, these materials are at the forefront of crafting durable and resilient infrastructure.