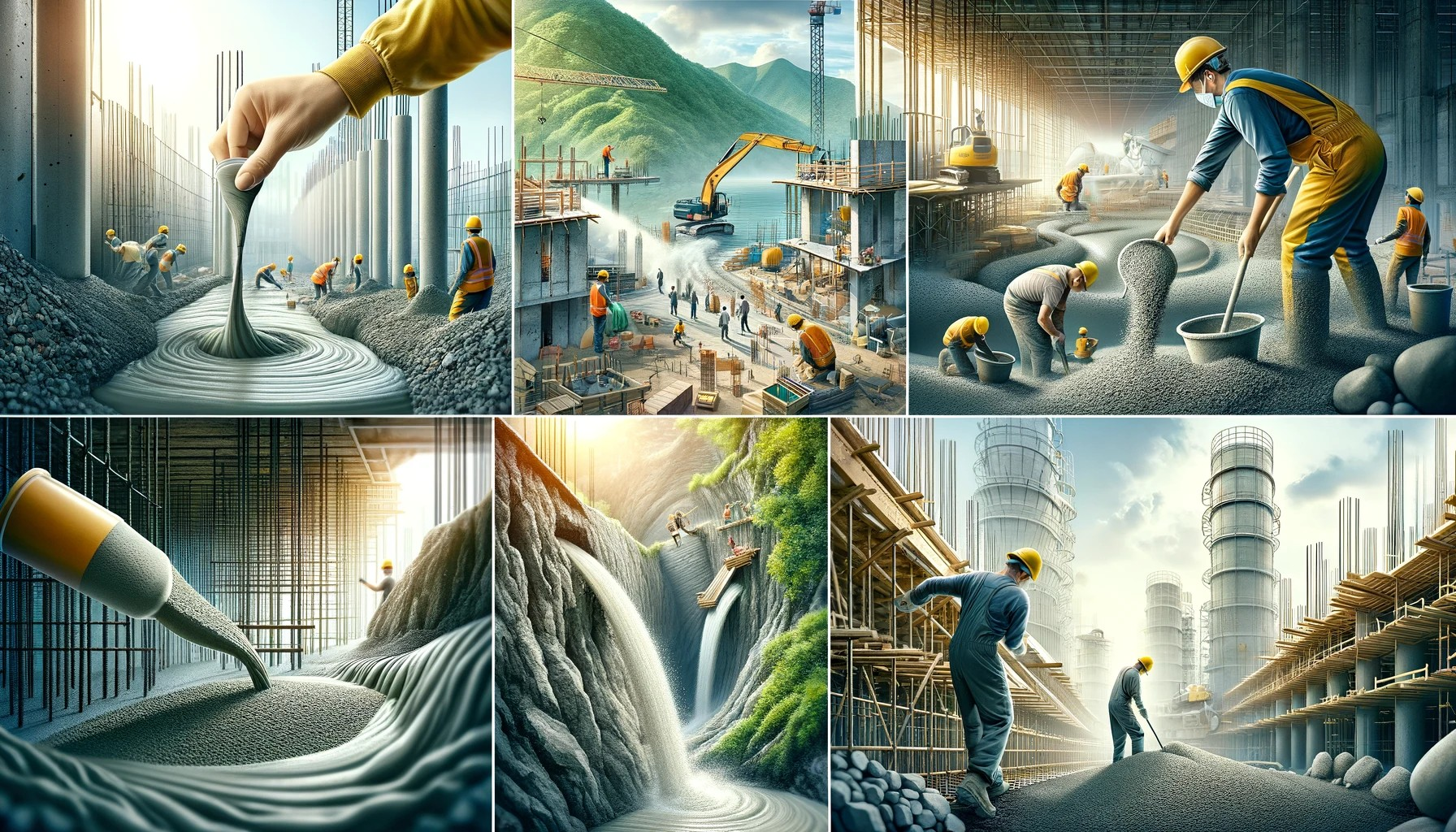

Building Stronger Foundations: The Impact of SAF on Cement Dispersion Technology

The quest for stronger, more durable, and more cost-effective materials is ongoing in the construction and infrastructure development world. One such material that has significantly impacted the industry is Sulfonated Acetone Formaldehyde (SAF), also known as Acetone Formaldehyde Sulfonate (AFS). This innovative compound has transformed cement dispersion technology, providing numerous benefits that contribute to building stronger foundations and more resilient structures.

What is SAF?

What is SAF?

Sulfonated Acetone Formaldehyde (SAF) is a water-soluble polymer derived from acetone and formaldehyde, modified by sulfonation. This chemical modification enhances its dispersing properties, making it an ideal additive for various industrial applications, particularly in the construction industry. SAF is known for improving cementitious materials’ workability, strength, and durability.

Enhancing Cement Dispersion

One of the primary uses of SAF in the construction industry is as a dispersant in cement. When added to cement, SAF helps to evenly distribute cement particles within the mix, reducing clumping and improving the overall consistency. This enhanced dispersion leads to several key benefits:

- Improved Workability: SAF increases the fluidity of cement mixtures without additional water. This improved workability makes pouring and shaping concrete easier, especially in complex forms and intricate structures. It also allows for better compaction, reducing the likelihood of voids and weaknesses within the concrete.

- Higher Strength and Durability: SAF enhances hydration by ensuring a uniform distribution of cement particles. SAF leads to a denser and more cohesive concrete matrix, which increases compressive and tensile strength. The improved durability of SAF-modified concrete makes it more resistant to cracking, shrinkage, and other common issues compromising structural integrity.

- Reduced Water Demand: SAF allows for a significant reduction in the water-cement ratio. Lower water content in the mix improves the concrete’s strength and durability and minimizes the risk of segregation and bleeding. This results in a more homogeneous mixture that is less prone to defects.

Applications in Construction

Applications in Construction

The benefits of SAF in cement dispersion are particularly valuable in various construction and infrastructure projects. Some notable applications include:

- High-Performance Concrete: In projects where superior strength and durability are essential, such as high-rise buildings, bridges, and industrial structures, SAF-modified concrete provides the necessary performance characteristics to meet stringent engineering requirements.

- Precast Concrete: SAF improves the workability and strength of precast concrete elements, such as beams, slabs, and panels. It ensures these components meet quality standards and perform reliably in their intended applications.

- Shotcrete: In tunneling and mining operations, shotcrete (sprayed concrete) requires excellent adhesion and minimal rebound. SAF enhances the sprayability and cohesion of shotcrete making it an ideal choice for these challenging environments.

- Self-Compacting Concrete (SCC): SCC is designed to flow easily into formwork and around reinforcements without mechanical vibration. SAF’s dispersing properties are critical in producing SCC with the right balance of fluidity and stability.

Environmental and Economic Benefits

In addition to its performance advantages, SAF offers environmental and economic benefits. By reducing the water demand and improving the efficiency of cement use, SAF contributes to more sustainable construction practices. Lower water consumption and enhanced durability lead to reduced maintenance costs and longer service life for structures, ultimately providing significant cost savings over time.

Conclusion

Sulfonated Acetone Formaldehyde (SAF) has emerged as a game-changer in cement dispersion technology, driving advancements in the construction industry. Its ability to enhance workability, strength, and durability makes it an invaluable additive for various applications. As construction projects demand higher performance and sustainability, SAF stands out as a key ingredient in building stronger foundations for the future.